Sample Transport Systems

Sample transport systems present tremendous opportunities for improved analyzer accuracy. Chemical and petrochemical industries around the world have clearly identified that yield, scrap and compliance improvements can be directly attributed to the effectiveness of the sample transport system. Analyzers will function only as well as the transport system yet this same system is often the most overlooked and misunderstood component. Electric and steam traced tubing provides process fluid freeze protection and temperature maintenance in a variety of analytical and process instrumentation applications including impulse, process, and sampling lines.

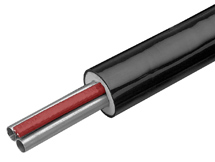

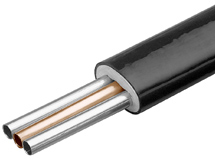

Selecting the right process tube for use in analyzer sample transport systems requires consideration of process and application conditions. There are a wide variety of metallic and non-metallic tubes available: welded and seamless 316 series stainless steel and more exotic alloys are also used. Common non-metallic tube materials are PFA, PFE, and PTFE fluoropolymers polyethylene and Halar (ECTFE). Some bundles may also contain coaxial tubing (tube-in-tube) or unheated tubes for calibration gas and blowback lines.

Improper tube selection may lead to a failed analyzer systems caused by adsorption, contaminants in the tube, corrosion stress cracking or gas permeation. Restricted sample flow, long sample lag times, and kinking are also problems often related to tube selection.