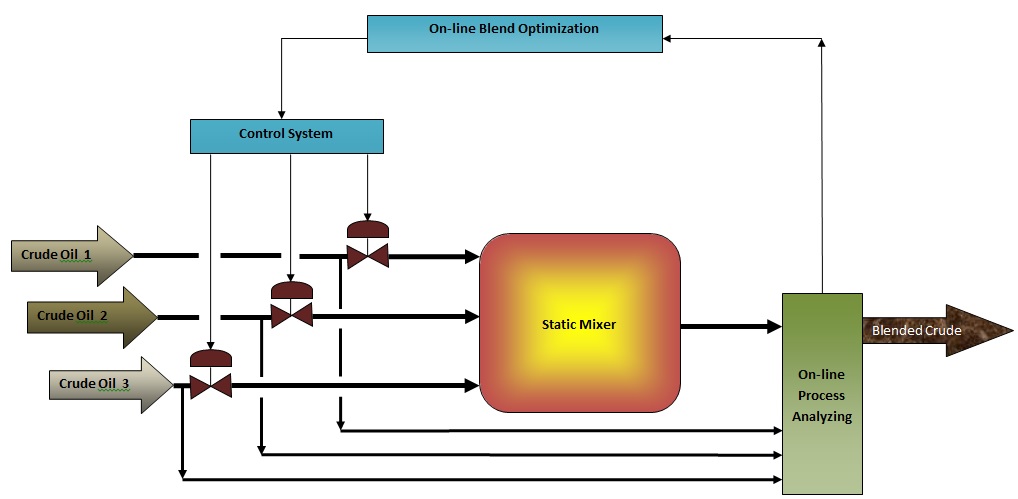

Production of motor fuels is executed by means of blending (compounding) of different components and octane-increasing additives in special blenders according to pre-developed receipt. The feed streams enter the blenders through measuring lines allowing simultaneous control of all stream ratios. Online analyzers continuously analyse qualities of the feed streams and final products at the blender output. Results of analyses are sent on a real-time basis to optimization system to define optimal formula of the blended product and to calculate the volume flow by the each of control loops.

Addition of all streams gives the total flow of the final product through the blender, quality of which strictly conforms to specification providing minimal cost of the final product.

The Beacon 3000 system is the newest analyzer providing the technological process control in the near infrared region of optical spectra. The master analyzer is located in Central Equipment Room protected from environmental effects. The master analyzer is connected with periferal metering modules installed directly in the technological line at the distance up to 3 km from it by means of fiber optic cable. Up to 8 periferal modules can be connected to one master analyzer. The peripheral module does not require power supply and has not any moving parts. Being totally optical it is explosion-proof module requiring neither special container nor protective case.

The patented material used for fabrication of windows is resistant to contamination, so it is not necessary to disassemble and clean the metering module. The measuring sample does not require complex preparation that also increases the system reliability.