MOD-1040 Oxygen Analyzer is designed to provide accurate and reliable measurements of oxygen levels in high-pressure pipeline, making it ideal for a range of industrial applications. With its advanced optical sensor technology and rugged construction, MOD-1040 delivers precise measurements even in the harshest of conditions. Its user-friendly interface and intuitive controls make it easy to operate, while its compact design allows for easy installation directly on process pipe without any sample extraction.

Whether you’re working in the oil and gas industry, hydrogen production, chemical processing, or any other process industry, the MOD-1040 Oxygen Analyzer is the ideal solution for precise and reliable oxygen measurement in high-pressure applications.

Key Features and Specifications of the MOD-1040 Oxygen Analyzer

- High-accuracy measurement of oxygen levels up to 100%

- Explosion-proof certified: II 2 G Ex db IIC T4 Gb (IECEx ITS 23.0017, ITS-I24ATEX40694)

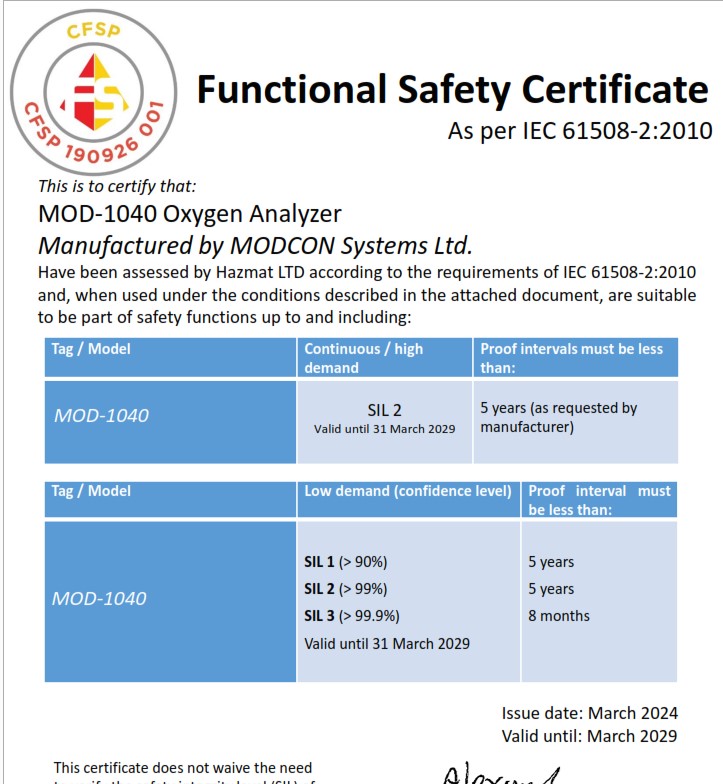

- Safety integrity level certified: SIL2 as per IEC 61508-2:2010 (020195:3266-1-P1)

- Resolution: 0.01% O2

- Response time (T90): <5 sec

- Ambient temperature: -10 to 60 deg.C

- Maximum pressure: 200 Barg

- Rugged construction and compact design for reliable operation in harsh environments

- Flexible installation options to suit a variety of industrial applications

Contact us to learn more about MOD-1040 Oxygen Analyzer

Industrial gas production systems, including those for hydrogen and oxygen, typically involve the use of equipment rated for both non-hazardous and hazardous locations. One approach to lowering installation costs is to utilize general-purpose equipment, but this may only be feasible if the risk of gas leaks is minimized.

Reducing the potential for leaks can create difficulties in sampling gas from high-pressure pipelines, making it challenging to perform accurate oxygen analysis. Traditional oxygen analysis technologies, including paramagnetic, zirconia, coulometric, and TDL, are not designed to withstand high gas pressures and therefore require gas sample extraction and conditioning prior to analysis. MOD-1040 allows for direct measurement of oxygen content in high-pressure pipelines, eliminating the need for gas sample extraction or conditioning.

MOD-1040 Process Oxygen Analyzer is not just another option on the market; it’s a fusion of precision, performance, and uncompromising safety standards. By utilizing fluorescence quenching technology, the MOD-1040 accurately measures oxygen content, a critical aspect in high-pressure green hydrogen production. Its advanced optical sensor technology is particularly suited for challenging applications, offering retractable process connections for easy installation, calibration, and maintenance. With precise measurements in harsh conditions and in-situ installation, MOD-1040 enhances operational efficiency and allows the reduction of hazardous area classification, simplifying designs and cutting costs. The MOD-1040 emphasizes safety, efficiency, and quality in hydrogen production, marking a new era in sustainable energy solutions.