Terminals

Terminals or tank farms are widely applied to store petroleum products, and to transport these products through pipelines, by  ships, by trucks or by railways to the end users. Terminals are used for a broad variety of products, such as crude oils, refinery distillates, gasoline, diesel oil, and other fuel oils. Commonly terminals include storage tanks, pipelines to and from the refineries, filling stations for road tankers, and filling stations for vessels.

ships, by trucks or by railways to the end users. Terminals are used for a broad variety of products, such as crude oils, refinery distillates, gasoline, diesel oil, and other fuel oils. Commonly terminals include storage tanks, pipelines to and from the refineries, filling stations for road tankers, and filling stations for vessels.

Many terminals operate as independent companies that provide storage and distribution facilities without necessarily being linked to a refinery.

The scope of terminal activities is not restricted to storage, distribution, import, and export only. Many term inals also provide blending services, such as crude oil blending, diesel blending, and gasoline blending, to blend raw materials or semifinal products into final petroleum products of well-defined specifications.

inals also provide blending services, such as crude oil blending, diesel blending, and gasoline blending, to blend raw materials or semifinal products into final petroleum products of well-defined specifications.

Quality control is an important task in terminal operations, to guarantee that the products, which are received at the terminal or are provided to the end-user are in full compliance with their required specification.

Online analyses of quality parameters have the advantage of the ability to provide real-time quality data of petroleum products passing through different pipelines, and by that preventing acceptance or delivery of off-spec material by the terminal.

On-line process analyzers are not only important in quality control of raw materials and products but also in blending management. Continuous measurements of the blend properties are essential to prevent:

- The formation of blends that are not complying with its requirements

- Unnecessary excessive blending time

- Giveaways

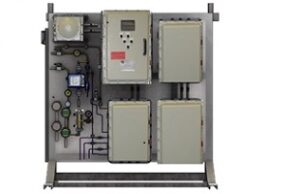

Modcon Systems has longstanding experience and expertise in online analytical solutions and implementation of entire turnkey projects for refineries and terminals.

Modcon’s solutions for terminals include:

- The optimized blending of petroleum products such as gasoline, diesel crude oils, etc.

- On-line analysis of products received at the terminal

- On-line analysis of final products loaded on tanks, trucks, or ships

- On-line analysis of stored products

Modcon Systems provides complete, integrated analyzer systems and all related services from initial engineering through manufacturing, testing field start-up, and training.

Modcon System Solutions comes to satisfy its customers with overall cost-effective solutions to maintain the highest product quality, maximum safety, and minimum environmental burden.