Oil Refinery

The objective of modern oil refinery plants is to manufacture high-value and on-specification products at optimal cost and minimal environmental burden. Therefore on-line qualitative and quantitative measurements of physical properties and chemical composition are an indisputable requirement.

Process analyzers can offer a substantial contribution in maintaining the required specification limits while reducing energy requirements. With fluctuating crude oil prices, the reduction of the energy required for production has become the main target for modernization.

Petroleum process analyzers based on standard ASTM methods are not dependent on crude quality and other factors, but their response time is longer and maintenance is expensive. Near-infrared (NIR) Analyzers are usually simple to install, very reliable, and require minimum maintenance.  The new innovation represents NIR Analyzer located in the control room and connected via telecommunication fiber optics to the field units installed as needed in the process.

The new innovation represents NIR Analyzer located in the control room and connected via telecommunication fiber optics to the field units installed as needed in the process.

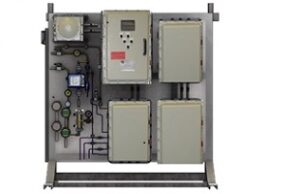

The combination of Discrete Analyzers with NIR Analyzers enables the user to achieve performance, accuracy, and availability which is difficult to reach using only one technology. The trend over the past years is toward prefabricated analyzer houses which are pre-piped and pre-wired with all analyzers, sample systems, and utilities, complete assembly tested at the factory, and shipped to the site as a single package. Site installation work is kept to a minimum, thanks to turn-key responsibility when one team of specialists manages the project from start to finish.

Modcon will assume total systems responsibility, so you can obtain all project requirements from a single source. This provides a single channel for communicating and interfacing, and it helps achieve consist ent design, assembly, and component selection. Modcon provides complete, integrated analyzer systems and all related services from initial engineering through manufacturing, testing, and field start-up.

ent design, assembly, and component selection. Modcon provides complete, integrated analyzer systems and all related services from initial engineering through manufacturing, testing, and field start-up.

- Total Analyzer Systems Integration

- Sample Conditioning Systems Design

- Testing, Field Services, Training

- Continuous Emissions Monitoring

One team of specialists manages your project from start to finish. Modcon’s staff has extensive experience with virtually every type of process analyzer, as well as with various forms of packaging such as stainless steel or fiberglass buildings, galvanized-steel buildings, cabinets, and racks. Years of in-plant experience guarantee the best available technology in your system designs.

- Salt Content Monitoring

- Efficient Crude Oil Blending

- Economics of Process Analysis for Efficient Utilization of Crude Oils

- Remote Sensing – Beneficial Strategy in Refinery Optimization

- Alkylation unit control optimization

- Centralized Refinery Process Monitoring

- Effective Refinery Process Control

- Reducing Costs of Gasoline Blending

- Advanced Blending Solutions

- Economizing Gasoline Blending with the Beacon 3000

- Enhanced Safety by Beacon 3000 NIR Process Analysers

- On-line NIR Analysis in Extraction Complex

- On-line NIR Analysis in Aromatic Complex

- Combined Technologies for Efficient Refinery Optimization

- Intensification of Conventional Process Industry Through In/Online Analysis

- Optimized Utilization of FCC Catalysts

- CDU optimization

- Optimized Blending of Butane in Gasoline