A major strategy in process industries is to run industrial processes at the highest economic performance through involvement of hardware and software solutions. Traditionally petroleum industries are using controllers ranging from proportional controllers to advanced predictive based controllers such as Model Predictive Controllers (MPC). The most of these systems were developed 20-30 years ago and requires careful analysis of the process dynamics, development of abstract mathematical models and derivation of a control law that meets certain design criteria. The drawbacks of this well-proven technology are mainly related to complexity of dynamic models and their continuous maintenance requirements to accommodate feedstock changes, process improvements and deviations in product demands as a result of the changing global economy.

Just like internet companies that can create high value by optimizing the commercial assets in the consumer market by data analytics, petroleum industry can also generate high value by optimizing their assets from analytics of machine and processes data they have acquired from the operations and productions. Modern machine and deep learning technologies enables simply interacting with the process and incrementally improving control behavior.

The AI-based approaches started to emerge in the late 1990s as the third generation of optimization methods. The idea is to use a limited number of design trials (called sample points) to construct a machine-learning model between the design variables and objectives/constraints. However, very little was made in AI-based approaches and more than 85% of data science projects fail to make it into production.

The purpose of Modcon-AI HW/SW package is to provide refinery with set of modern optimization tools, which enables connectivity, validation and prediction of main KPIs, to take the correct decisions to maintain and improve effective industrial processes management. The implemented in this solution artificial neural network (NN) dynamic models enables to calculate and predict physical properties and chemical compositions for different process streams, and proposes required set points, that will accomplish the calculated predictions.

Deep reinforcement learning (DRL) is a powerful machine learning technique, which can be effectively used to optimize industrial processes for different strategic goals, allowing to shift focus intelligently and confidently. Reinforcement learning makes use of algorithms that do not rely only on historical data sets, to learn to make a prediction or perform a task. Just like we humans learn using trial and error, these algorithms also do the same. A reinforcement learning agent is given a set of actions that it can apply to its environment to obtain rewards or reach a certain goal. These actions create changes to the state of the agent and the environment. The DRL agent receives rewards based on how its actions bring it closer to its goal.

DRL agents can start by knowing nothing about their environment and selecting random actions. Because reinforcement learning systems figure things out through trial and error, it works best in situations where an action or sequence of events is rapidly established, and feedback is obtained quickly to determine the next course of action — there is no need for reams of historical data for reinforcement learning to crunch through. That makes DRL perfectly suitable for hydrocarbons processing optimization tasks using established metrics in the form of inputs, actions, and rewards.

Being a powerful tool, which requires no historical data for reinforcement learning, DRL has one significant weakness, which makes it more difficult to implement for hydrocarbons processing with wide ranges of operation. DRL is likely to improve performance only where the pre-trained parameters are already close to yielding the correct process steams quality. The observed gains may be due to effects unrelated to the training signal, but rather from changes in the shape of the distribution curve. Therefore, there is a need in real-time monitoring of process yields, rather than only their prediction using the pre-trained models. This can be reached using the on-line analyzers installed in the process to determine the chemical composition or physical properties of substances involved in hydrocarbons processing.

The starting point for choosing which KPIs are key to a particular process, should be to be focused on those, that can characterize the given inputs against target outputs. Modcon-AI is using a well-proven technology of setting network input and output parameters, input preprocessing settings and output postprocessing settings, using weight initialization techniques to match input/target data.

The obvious way for this exercise in downstream industry is to apply KPIs, which are directly related to the quality of process streams, i.e. physical properties and chemical composition of the incoming material and outgoing products in each process unit. This enables to establish a simplified process’ digital twin, which describes process objectives and includes in decision tree only those KPIs, which are more relevant for the process efficiency.

Additional KPIs to be considered are related to safety, security and environmental requirements, which shall be applied as a constraints. This method enables overall process optimization through integration of the network input and target KPIs, using linear programming techniques to maximize the overall profit.

Main KPIs, which shall be considered here are as follows:

- Physical properties and chemical compositions for different process streams – using pressure, temperature, flow, level and other measurements by field instrumentation. These predictions shall be validated against process analyzers and laboratory results, including correction by Freetune

- Early leak detection – using pressure, flow, acoustic, seismic, electromagnetic, mechanical, chemical, thermal and other pipeline measurements. The system analyses the calculated pipeline state, searches for anomalies that suggest a leak and determines their location

- Emission sources localization – real-time operational implementation of dynamic model and monitoring system for detailed post-event analysis that allows to pinpoints the source of a chemical release using meteorological data and concentration measurements from the analyzers/sensors

- Advanced corrosion analytics – using deep learning technology powered by process analyzers and high temperature hydrogen attack, partial pressure and length of exposure limits methodologies

- Improving process units yield and safety – leverage existing OT data infrastructure to enable the use of machine learning and deep learning technologies.

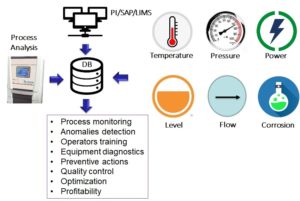

Modcon-AI connectivity to industrial data bases is provided using the standard ODBC, OPC and Modbus TCP/IP communication platforms. Process data is extracted from existing PI real-time data management system, which is normally secured by unidirectional information flow and can be easily reached by external devices. Additional connectivity to LIMS, IMS and other data bases enables to get data which isn’t readily available in PI.

Using the information from the process, Modcon-AI performs data acquisition, monitoring, verification, validation, statistical evaluation, correction and reporting of measurements results. Prediction of main process KPIs, such as physical properties and chemical compositions for different process streams is provided by multivariable data analysis algorithms. Deep learning and big data analytics functionality is provided by neural network learning tools and can be as option installed offline, in order to eliminate a need in continuous cloud computing.

Economic managements requires to combine different technologies, hardware as well as software that provides an entire overview of the operation of the process units based on quality data, as well as marketing, volume, supply of crude oils, energy etc. Combining logistic and technical hardware and software forms a basic tool from managers to operators to take the correct decisions to maintain and improve successful refinery management.

Further investment in the PA, AI and ML technologies for sustainable development means for Modcon adopting business strategies and developing advanced technologies that meet the needs of the enterprise today while protecting, sustaining and enhancing the human and natural resources that will be needed in the future.

For further details and specifications

Choose the PDF files to download

3 thoughts on “Artificial Intelligence”