Advanced Blending Solutions

Blending operations became a major strategy as an answer to the ever-growing competitions between refineries. The strategy of blending crude oils and refinery products is to increase refining margins, without affecting required physical properties of the blends. Utilization of cheaper crude oils in crude oil blends and maximization of low cost refinery intermediate products in final blends are basic operations to achieve this goal.

Types of Blending Processes:

- In-tank Blending – all component are fed into a mixing tank and stirred until a homogeneous blend is achieved.

- In-Line blending – all components are continuously and simultaneously passed in the correct ratio through a static mixer, providing directly a final blend of required quality.

The benefit in-line blending over in-tank blending:

- Instantaneous production of the blend

- Material in-spec throughout entire blending process

- Rapid availability of the product

- Storage of minimized small stocks of the product in a plant

- Less capital investment in mixing tanks and stored products

- No large occupation of mixing tanks, leading to low space requirements

- All tanks designated to final products

- Rapidly reacting to changes in production planning

- Rapidly reacting to fluctuations in raw materials

- Reduction of costly giveaways

- High production capacity – no lack time due to time-consuming laboratory analyses

To efficiently and error-less operate the blending process, on-line process analyzers are inevitable

to instantaneously measure quality properties of component feedstock streams and blend streams. Quality parameters are on-going provided to the operators, the DCS or to any other automatic optimization system to guarantee the optimized conduction of the blending operations, based on the following features:

- Real-time and on-line corrections to provide directly a blend of requested predetermined quality properties.

- Reduces the need for corrective re-blending of an entire tank, as well as unnecessary “giveaways”.

- On-line analyzer validation and control

- Check component availability.

Simulation software, such as LP (Linear Programming) modeling is frequently used to predict the ratio components that provides the lowest cost blend, still conforming its required specification.

In general, the fundamentals of this software are a database containing historical analytical assays and other analytical data that has been collected from a variety of different blends and components to be blended. However, blending processes are dynamic processes, associated with fluctuations in feed properties. Efficient in-line blending requires continuous measuring of required quality parameters.

Optimization of the blending process to its highest extent requires continuous updating of the simulation model by adapting to real time analytical date. Correlative on-line analyzers, such as NIR and ASTM based, provide a broad range of different real time analytical data of feedstock and final blends in a continuous mode.

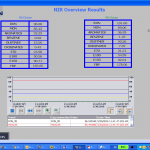

Fundamentals and optimized functions of effective blending simulation software includes:

- Measuring physical properties of component streams to be blended

- Measuring the blend properties

- Determination and control of the ratio of blend components to achieve a well-defined blend specification

- Ratio limits

- Properties constraint of the blend

- Constraint limits

- Prices of feed-stock and final blends

- Check component availability

- Volumes of final blends required by the consumers (internal and external)

- Cost of various blend compositions

- Alarms and Controls

In case of crude oil blending, also must be taken into consideration:

- Limitations due to engineering properties of the CDU and relevant pipelines. (Construction Materials, corrosion, viscosity, heating/cooling, overhead reflux, reboiler).

- Required volumes of different distillates.

- Maximum production capacity of each required distillate and bottom product.

The application of the integrated system of on-line process analyzers and simulation model software provides advanced tool to economize blending operations based on real time analytical data, combined with economic parameters. This combination is the starting point in a new and advanced concept of blending.

Although interdependent, it is not sufficient to base the analytical system on single measurements, such as usually provided by discrete ASTM based analyzers, which measure one specified property each, but a broad range of different physical properties must continuously be analyzed. Efficiently, this is only achieved by incorporation of correlative, and multi property ASTM analyzers such as Beacon-3000, NIR and the MOD–4100 process analyzers. In these spectroscopy and ASTM based process analyzers chemometrics calculate quantified physical properties from the correlation between spectral data and quantified values of physical properties.

Whereas, transparent light blending process streams, such as gasoline are also measurable by optical spectroscopy methods, such as NIR, heavy and opaque process streams are preferably or solely analyzable by the MOD-4100 ASTM based process analyzers.

Integrated blending operations are applicable to:

- Crude Oil Blending

- Gasoline Blending

- Diesel (gasoil) blending

- Fuel oil and Bunker oil blending

Gasoline Blending

Gasoline is a blend, containing a broad variety of different process streams, such as naphtha form the CDU, butane gas, Naphtha from the FCC, Reformate, isomerate and optional oxygenates such a MTBE. Gasoline must comply with stringent specifications according to well-defined standards. Installation of online process analyzers is an indisputable requirement to guarantee in-spec production of gasoline at lowest cost. Laboratory test are too time consuming in the gasoline blending to guarantee continuous production of in-spec gasoline. A major gasoline property are RON and MON. In many cases these properties are achieved by incorporation expensive RON enhances like oxygenates. Among further limitations to be taken into account are restrictions to the

aromatic content and the benzene content in gasoline.

Conventionally, on-line RON mechanical knock engines are used for on-line

measurement of the octane number of the gasoline, to verify the blend con

forming with its required octane number, but being as low as possible to reduce giveaways of highly expensive gasoline components. Mechanical online process analyzers are expensive, and requires investing huge amounts of resources in purchase, maintenance and expensive critical spare part costs. Further to that, any shutdown due to a mechanical failure of these analyzers will result in an

unnecessary an expensive shutdown of the blending station. On-line NIR correlative process analyzers, such as the Beacon 3000, have the capability to measure a broad variety of different specification parameters by one single measurement, and by correlation between spectral measurements and quantified quality properties.

In the absence of mechanical parts, these analyzers are of low cost, not only in purchase but also in maintenance.

The NIR technology enables by either operators or automatic to fine-tune the ratio between process streams, which will give the minimum required but in-spec guaranteed knock properties, while omitting giveaways.

Modcon proposes to use the following criteria for the decision on the success of the blend control and optimization system during

the test runs of the gasoline in-line blending system:

1. Minimization of quality give away

The blend control and optimization system will execute the blend using optimized blend recipes that generate minimum quality give away. The actual quality give away is depending on the actual component availability and as such no number can be guaranteed. Instead, Modcon guarantees that the integrated tank quality for a set of 3 blend qualities is meeting the upfront calculated blend target. If the actual blend economics drive the blend to meet different constraints as expected during the blend set-up, then this shall be acceptable as well.

2. Generation of optimized blend recipes

Generation of optimized blend recipes for sequences of up to 5 blends, which match the product demand and keep the component inventory within the operational window of the related component tank storage. The generation of a feasible blend sequence is limited to situations in which there is a theoretical solution available. It excludes infeasible blend situations.

Diesel Oil Blending

Petroleum derived diesel (called as petro diesel) is a mixture of straight run product (150 °C and 350 °C) with varying amount of selected cracked distillates and is composed of saturated hydrocarbons (primarily paraffins including normal , iso , and cycloparaffins), and aromatic hydrocarbons (including napthalenes and alkylbenzenes). Required standardized physical properties are in general obtained by blending finetuning the ratio between straight run diesel and cracked distillates, and in many cases also diluted with kerosene, especially to guarantee different cold plugging temperatures according to seasonal temperature deviations. It is of course up to the refinery to reduce the cost of the final blend to the highest extent, which means maximum low cost diesel components, such as cracked materials, and minimum amounts of more expensive distillates such as diesel distillate kerosene. Increasing the benefit of the diesel blend requires blending of maximum quantities of low cost diesel components with lowest possible quantities of straight run diesel oil and kerosene. Integration of NIR process analyzers are effective tools to achieve this goal. Various quality properties are measured, instantaneously, without needing conventional ASTM based analyzers or on-line cetane engines that require a high investment in purchase and maintenance. Real time analyses allows on-line to optimize the blending recipe that will give lowest cost in-spec gasoil, especially when the analytical data is combined with model software to continuously calculate and optimize gasoil blend compositions. Incorporation of NIR process analyzers for continuous on-line and real time determination of the quality properties in cooperation with an appropriate software are the fundamentals to increase of the percentage of cracked components in the final inspec diesel blend. As the ratio cracked material vs distillates dominates in the production cost determination of the final blend, the concept of an integrated system of on-line process analyzers is definitely an advanced concept in diesel oil blending with the benefit to reduce the cost of the final blend, and by that to increase the refining margin of the refinery.Fuel Oil Blending

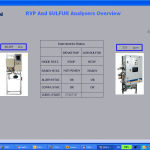

Heavy fuel oils and marine bunker oils are blends of heavy refinery products, distillation residues, visbraking residues, thermal cracked residues, and in many cases diluted with CDU distillates such as kerosene, for viscosity adjustment. A broad range of different types of fuels oils as well as bunker oils are brought on the market. These differ ent types are distinguished by differences in viscosity. These materials are of high viscosity, inferior flow properties and with physico-chemical properties that do not comply with required specifications. Transformation of these materials as fuel oils or as bunker oils requires blending

them with lighter, but still low cost petroleum products such as diesel oils and

kerosene, with the target to adapt the major specification properties of interest in fuel oil and bunker fuel oils. These are the viscosity, specific gravity, Conradson carbon residue, flashpoint and sulfur to their requested specification. Of special interest in blending fuel and bunker oils is to prevent precipitates caused by blending of incompatible feedstocks. Fuel oils and bunker oils are heavy opaque and dense mass. This makes the MOD-4100 process analyzer the only available correlative analyzer that has the capability to conduct multiple property analyses by one single analyses.

This feature is of great importance during the blending procedure in the production of different types of fuel and bunker oils. Efficient blending of fuel oil and bunker oil is conducted in many cases at elevated temperatures to enable flowing of the feedstocks through pipelines. Fast blending is preferred. Re-blending or repair blended batches that are of border-lined or off-spec quality must be eliminated. The challenge to optimize fuel blending lies in the integration of MOD-4100 process analyzers with blending software. The MOD-4100 process analyzers measure the quality of different feedstocks to be blended, and the final product.

Transformation of the analytical data into an operating system that automatically calculates, adjusts and fine-tunes the type and ratio of feedstock, such as various cracked materials, various distillates and bottom products, to blend,. The optimized blending recipe and its MOD-4100 process analyzer based process

control system guarantee the production of such a material, having the required properties and is of lowest cost. Furthermore, the integrated MOD-4100 into predicting blending software enables rapidly to switch between the productions of different types of fuel and bunker oils, according to the demands of

the refinery or the fuel production company.

Crude Oil blending

In the past refineries distilled predominately-light crudes. Nowadays, due to the global competition, shifting from naphtha to heavier distillates, and the production of FCC naphtha for gasoline production, a major strategy in refinery economizing, requires increased utilization of heavy or opportunity crudes. The major operational cost of a refinery is based on the price of the crude oil, which is estimated at 80% to 90% of the cash flow. Reducing the cost of the crude feedstock, without changing the range and volumes of high valued distillates, increases the refining margin, and thus the profit of the refinery.

Most refineries are not constructed from an engineering point of view and from materials that can cope with heavy and corrosive crude oils. Refinery economics requires minimizing the cost of their crude oil feedstock by incorporation of maximum quantities of heavy and opportunity crudes into a blend with light sweet crudes, being able of processing in the available CDU equipment, with a maximum yield and capacity of most desired valuable distillates.

Verification of compliance of the crude blend with its required specification throughout the entire production process is the keystone to economic blending with high efficiency. Preventing inferior quality of the blend requires immediate execution of corrective actions in case of discrepancy between real time and required quality properties.

The following conditions must be taken into consideration when economizing crude blending operations:

1. On-line and continuous measuring of a variety of different physical properties of opaque components to be blended and the blend alike. Crude Oil process analyzers measure a variety of different quality parameters in one single analysis, which allows real time adjustment of the ratio between different crude oils to be blended.

2. Incorporation of heavy, opportunity and other low cost crude oils to the highest extent into the blend.

3. Composing the most economic blend that can be processed in the available CDU applying feasible process conditions that will lead, at lowest cost, to the highest possible process yield and the highest production capacity of demanded distillates.

4. The aim of the composition of the blend is also to reduce the corrosion to its minimum, and by that to prevent any unnecessary shut downs for maintenance and repair of corrosion failures.

Crude blending is a dynamic process. Fluctuations in physical properties of the crude blend occur by deficient homogeneity,

switching between crude oils of different batches, switching between different components. To eliminate these fluctuations of influencing the final blend, the blending recipe must continuously update itself according to the quality parameters of the blend, to

guarantee the formation of a uniform blend, produced throughout the entire blending process. Crude Oil process analyzers are effective in measuring crude oil, as, in contrast to optical spectroscopic methods, opacity is not a restricting parameter in its application. The MOD-4100 process analyzer provides accurate on-line real time analytical data of the quality of the blend in process.

Refineries and blenders use general linear program software to calculate and predict a blend of a particular quality and properties that will provide the highest quantities of planned distillates and at lowest cost, when conforming the calculated process conditions that are adaptable to a CDU. The blending recipes are composited from historical data of different crude oil assays. However, deviations between calculated and real time quality properties may lead to off-spec or borderline material, if not treated properly. Based on analytical data provided by MOD-4100 process analyzers, manually, or automatically continuous adjustment of the ratio between different feedstock streams to be blended, and by that to maintain a blend maintaining a constant in-spec quality.

To give an answer to the increased required consumption of heavy and opportunity crudes in blending processes to minimize the cost of the CDU feedstock and the dynamics during blending of different crudes, MOD-4100 measurements and crude blending model software are integrated into one package.

MOD-4100 sends real time analytical data to the blending model software. The data serves to continuously adjust and fine-tune the model of the predicted blend, and to correct the ratio between different crude oil feed stream, to provide that blend that will result in the most beneficial refining margin.

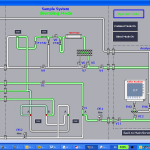

Modcon’s turn-key solution, establishes an advanced blending system by integration of on-line process analytical results with blending simulation software.

For further details and specifications

Choose the PDF files to download

Remote Connection Operator Iinterface