Fluidized Catalytic Crackers (FCCs) play a crucial role in modern refineries, converting low-cost heavy distillates into high-value gasoline naphtha. As refineries increasingly process a wide range of crude oils, including cheaper heavy crudes, the FCC process has become essential for maximizing gasoline production. To fully optimize the overall FCC process and increase revenue, it is crucial to measure the interlinked physical properties of feedstock, intermediate, and final product process streams. Near Infrared (NIR) process analyzers have proven highly effective in achieving this optimization.

The FCC process involves catalytic cracking, catalyst regeneration, and fractionation. Large molecules in the feedstock are cracked into smaller molecules through contact with a fluidized bed catalyst. Unlike thermal cracking, catalytic cracking involves carbonium ions and produces a range of products, including gasoline, light cycle oil, residual oil, and coke. The reactor temperature, feed preheat temperature, catalyst circulation rate, catalyst activity, and recycle rate are key variables affecting cracking yield and product conversion.

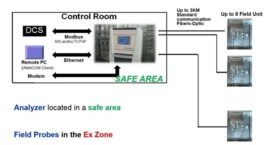

Optimizing the FCC process requires controlling variables in both the cracking and fractionation processes. Continuous monitoring of physical and chemical properties of process streams is vital for immediate adjustment of process parameters. Near Infrared (NIR) analyzers, as correlative analyzers, offer a significant advantage in this regard, providing multi-property remote analyses with a single instrument. Beacon-3000 process NIR analyzer can effectively measure physical properties in real-time, enabling the estimation of heavy feed conversion into light cracked products.

Integration of Beacon-3000 NIR process analyzers with Modcon.AI simulation software enhances the optimization of the complex FCC unit. The software calculates the impact of feedstock and process conditions on various parameters, including product yield, catalyst recycling, and coke formation. Real-time measurement of physical and chemical properties by NIR analyzers allows for continuous validation and improvement of digital twin models. This integration enables the FCC unit to operate in its most profitable and economic mode, significantly enhancing refinery revenues and profitability.

In conclusion, the evolution of the FCC process has allowed refineries to efficiently process heavy crude oils, significantly increasing gasoline production. FCC units are economically crucial for refineries, and their profitability depends on continuous process analysis and optimization. Real-time monitoring of physical and chemical properties using Beacon-3000 NIR analyzers, coupled with Modcon.AI software, ensures efficient adjustment of process conditions. This optimization leads to increased catalyst efficiency, reduced energy consumption, and enhanced production of gasoline components.