Process Analyzer Houses

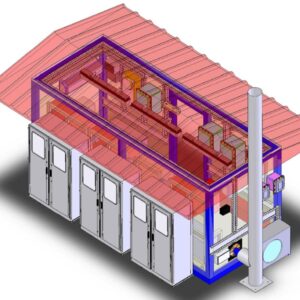

Modcon Analyzer Houses are versatile enough to accommodate virtually any combination of required analyzers, sample conditioning systems, and analyzer management systems.

The analyzer houses normally have a facility for remote real-time monitoring, diagnostics, and maintenance via a secured industrial network, offering complete remote access solutions through a choice of embedded routers using PSTN, ISDN, GPRS, or EDGE technology. The embedded Industrial Security System addresses the important issue of protecting Industrial Networks from modern cyber-security attacks.

Modcon provides complete integrated analyzer systems and all related services from initial engineering through manufacturing, testing, and field start-up. Analyzer systems are normally supplied and installed in special Analyzer Houses including air-conditioning, power distribution, lighting, termination and junction boxes, gas and flame detection, relevant piping, and wiring.

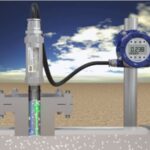

Process sample probes and sample transport lines designed to ensure representative and rapid sampling, avoiding the possibility of contamination or dead volume. Sample Conditioning systems to provide the sample in a state and condition compatible with the measurement technique used by analyzers. Sample recovery systems, stream selection facilities, telephone modem connections, furniture, special equipment and tools, etc.

One team of specialists manages your project from start to finish. Modcon’s staff has extensive experience with virtually every type of process analyzer, as well as with various forms of housings such as stainless steel or fiberglass buildings, galvanized steel buildings, cabinets, and racks. Years of in-plant experience guarantee the best available technology in your system designs.

Complete Analyzers Systems are normally equipped with the following main facilities:

- Analyzer Houses including air-conditioning, power distribution, lighting, termination and junction boxes, gas and flame detection, relevant piping and wiring

- Process sample probes and sample transport lines designed to ensure representative and rapid sampling, avoiding a possibility of contamination or dead volume

- Sample Conditioning systems provide the sample in a state and condition compatible with the measurement technique used by analyzers

- Sample recovery systems, stream selection facilities, telephone modem connections, furniture, special equipment and tools, etc.

The electrical classification and safety of analyzer shelters, process instrumentation, and interface equipment is a subject of great importance since the most of petrochemical process locations have been determined as a hazardous area. The choice of proper equipment and protection methods initially involves the determination of the nature of the hazards at the location. Modcon applies all available methods of protection, such as intrinsic safety, flameproofing, pressurization, encapsulation, increased safety, powder filling, oil immersion, etc. Modcon has an excellent facility specifically designed for performing integrated systems assembly and testing. The technical staff has a thorough knowledge of the National Electrical Code, purging requirements, and all necessary aspects of packaging. Modcon will assume total systems responsibility, so you can obtain all project requirements from a single source. This provides a single channel for communicating and interfacing, and it helps achieve consistent design, assembly, and component selection.

For further details and specifications

Choose the PDF files to download

Frequently Asked Questions about Analyzer House

What is an Analyzer House?

An Analyzer House, as provided by Modcon Systems, is a specialized facility designed to house a combination of process analyzers, sample conditioning systems, and analyzer management systems. These houses are equipped with essential features like air-conditioning, power distribution, lighting, termination and junction boxes, gas and flame detection, and necessary piping and wiring.

How does Modcon ensure secure remote monitoring and diagnostics of the Analyzer House?

Modcon’s Analyzer Houses feature advanced remote real-time monitoring, diagnostics, and maintenance capabilities through secured industrial networks. They offer complete remote access solutions using embedded routers that can utilize PSTN, ISDN, GPRS, or EDGE technology. Additionally, each Analyzer House is equipped with an embedded Industrial Security System to protect against modern cyber-security threats, ensuring safe and reliable operation.

What components are included in Modcon’s complete Analyzer Systems?

Modcon provides fully integrated analyzer systems that include not only the Analyzer House but also process sample probes and sample transport lines for contamination-free and representative sampling. The systems are equipped with sample conditioning systems to prepare samples for analysis, sample recovery systems, stream selection facilities, and necessary operational tools and furniture, ensuring a comprehensive solution for process analysis.

What measures does Modcon take to ensure safety and compliance in hazardous areas?

Recognizing the critical nature of safety in petrochemical process locations, Modcon adheres strictly to national and international safety standards. Their analyzer shelters and process instrumentation are designed with various protection methods, including intrinsic safety, flameproofing, pressurization, encapsulation, increased safety, powder filling, and oil immersion, based on the specific hazards identified at the location.

How does Modcon manage project execution for their Analyzer Systems?

Modcon employs a dedicated team of specialists who manage projects from inception through to field start-up. With extensive in-plant experience and a thorough knowledge of every type of process analyzer and housing, Modcon guarantees the application of the best available technology and design practices. Their facility is equipped for integrated systems assembly and testing, ensuring that all systems meet rigorous quality and performance standards.