BEACON 3000 – solution for optimizing alkylation unit control

BEACON 3000 – solution for optimizing alkylation unit control

In the past the octane number of gasoline, RON and MON, was mainly upgraded in gasoline blend by adding aromatics and MTBE, methyl tertiary butyl ether.

During the last decades gasoline production was influenced by the demands to reduce its benzene and aromatic content, as well as the use of MTBE. This ecological requirement along with the increase of the required octane number lead to production and consumption of alkylates for gasoline RON and MON adjustment.

Two units are critical for refineries, as they are of high importance in the increase of the octane number of gasoline blends.

- The FCC that cracks the heavy crude oil fractions by catalytic cracking into light naphtha and FCC gasoline, as well as light components such as butane and propene.

- HF Alkylation units.

Alkylation plants are key units in modern refineries to provide amounts of gasoline as required by the market. Alkylation unit process feed contains light olefins, such as butane and propene, predominately from the FCC, and isobutane.

In the alkylation process the olefines and isobutanes undergo catalytic reaction in presence of hydrofluoric acid to give isooctane that is used in gasoline blending to enhance the octane number to its required value.

Efficient operation of the HF alkylation unit requires stringent control of the process parameters. Feedstock may vary, impurities and water affect the catalytic reaction, and the process should give the highest conversion with a minimum of acid applied. Acid soluble oils (ASO), being an undesired HF consuming byproduct, may cause the process destabilize and run in a non-economic mode.

Laboratory analysis of the recycling HF content in the product is time consuming and dangerous. Optimized process control requires continuous on-line monitoring of the critical properties of the feed, the catalyst and the final product. It allows immediate adjustment of the process conditions to be executed for maintaining a stable and efficient operating of the alkylation unit.

An application for Modcon’s BEACON 3000 NIR process analyzer has been developed to control alkylation units.

Unique features are incorporated in the BEACON 3000 NIR process analyzer, which makes it:

1. Multiple stream analyzer

Multiplexertransfers the signals between the analyzer and up to eight fire- and explosion-proof flow cells. These are fixed on pipelines of the feed, products and the HF stream. Up to eight different process streams may be measured simultaneously.

2. Multiple property analyzer

Chemometrics enables spectral data, provided by the NIR process analyzer, to correlate with quantified physical properties or chemical composition. Multiple chemical and physical properties can be determined by one single measurement

3. Remote analyzer

Standard telecommunication fiber optics cable connects the analyzer with measuring cells that may be located at a distance of up to 3000 meters away from the analyzer. This enables placement of the analyzer in the central control room. On-line and real-time analytical data is provided to the operators to enable making fast decisions for running the process smoothly.

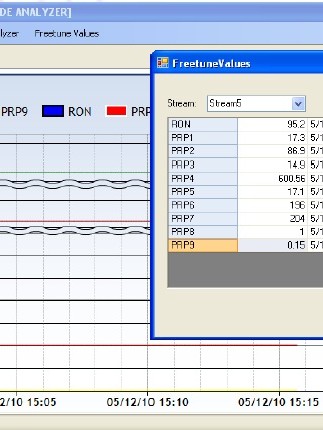

4. Equipped with incorporated FreeTune software

FreeTune is a proprietary software package to guarantee highest accuracy and reliability at any time. It surpasses other techniques by accurately quantifying properties without the need for model maintenance and fine-tuning. The FreeTune software validates NIR measured analytical results with laboratory analytical results, or with analyses of calibrated discrete ASTM analyzer. FreeTune includes guarding and correcting mechanisms to maintain the long- and short-term accuracy required for confident close-loop process control.

5. Low Cost Operation and maintenance.

Optimized composition of olefins, isobutane and alkylates in process streams as well as the ASO content and the HF concentration minimizes operational costs and losses of the alkylation plant. It will certainly contribute to revenue and profit of the entire refinery.