Refineries are a complex of different process units, which are spread out over large territories.

Most of these proce ss units are defined as unsafe Ex Zone areas, which requires investing in expensive protective solutions to place on-line analyzer in explosion and/or fire hazardous areas.

ss units are defined as unsafe Ex Zone areas, which requires investing in expensive protective solutions to place on-line analyzer in explosion and/or fire hazardous areas.

Mostly more than one analyzer is required to gain a minimum amount of analytical data to provide an

indication that the final product complies with its specification or does not.

Some questions that have to be asked now are:

- How many analyzers must be purchased to measure each process stream?

- What is the cost of each analyzer, especially when being Ex Zone protected?

- What is the cost of data acquisition, and transfer of the provided data to the DSC and to the control room?

- What is the cost of maintenance for each analyzer, and the cost of downtime of the analyzer during maintenance or repair?

- What are the safety concerns encountered with during maintenance operations of the analyzers?

In contrast to on site observation by on site analyzers, remote sensing is the acquisition of information about an object or phenomenon without making physical contact with the object. Fiber optics are typically used in remote sensing, either as the sensing element (“intrinsic sensors”), or as a means to relay signals from a remote sensor to the electronics that processes the signals (“extrinsic sensors”). Fibers have many uses in remote sensing.

Modcon Systems provides an exclusive remote sensing solution, which is of low cost as compared to conventional ASTM based

Modcon Systems provides an exclusive remote sensing solution, which is of low cost as compared to conventional ASTM based analyzers, and provides at real time on-line analyses of multiple physical parameters. The analyses are performed simultaneously by one single measurement. The Modcon Systems remote analytical solution is based on the Beacon 3000 Near InfraRed process analyzers. The system consists or intrinsic safe measuring probes, flow cells, which are free of electrical or moving parts. Low cost standard communication optical fibers connect up to eight of these measuring probes to a central NIR analyzer. The distance between analyzer and filed probes may be a far as three kilometers (2 miles). This technology enables installing the measuring probes in the unsafe Ex Zone, while the analyzer itself can be placed in any safe zone, like control room.

analyzers, and provides at real time on-line analyses of multiple physical parameters. The analyses are performed simultaneously by one single measurement. The Modcon Systems remote analytical solution is based on the Beacon 3000 Near InfraRed process analyzers. The system consists or intrinsic safe measuring probes, flow cells, which are free of electrical or moving parts. Low cost standard communication optical fibers connect up to eight of these measuring probes to a central NIR analyzer. The distance between analyzer and filed probes may be a far as three kilometers (2 miles). This technology enables installing the measuring probes in the unsafe Ex Zone, while the analyzer itself can be placed in any safe zone, like control room.

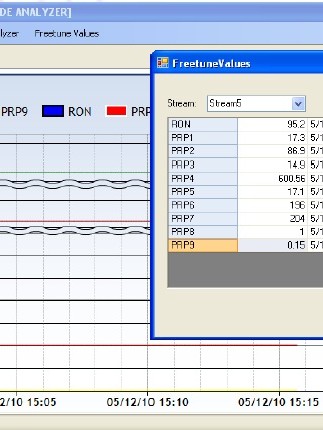

The analyzer sends a constant beam of light simultaneously to the field units connected to the analyzer. After passing through the sample, transmitted light returns to the analyzer. Optical multiplexing allows very fast switching between the optical fibers coming from different probes and allows measuring of different process streams almost instantaneously. Chemometric correlation between the measured spectrum and physical properties and incorporated Freetune model correcting software provide reliable analytical data of the different spots measuring sites.

from different probes and allows measuring of different process streams almost instantaneously. Chemometric correlation between the measured spectrum and physical properties and incorporated Freetune model correcting software provide reliable analytical data of the different spots measuring sites.

- Modcon’s Remote sensing technologies has the benefit that only one analyzer is required to perform multiple analyzes of physical properties in up to eight different measuring probes.

- No need for complicated sampling systems to change between different process streams.

- Measurements take place in a safe area, without bringing the sample to the analyzers.

- Measurement takes place at the place in safe areas, where the data is required.

- No need for expensive and complicated maintenance of the analyzers system.

- No need for expensive ATEX approved analyzers, analyzer cabinets or analyzers houses.

Modcon’s Remote sensing technology is implementable in a broad variety of different applications to optimize the process parameters in refinery distillation and process units, .with its low cost of acquisition and maintenance, provides an excellent opportunity to optimize the production capacity and product quality, while reducing the costs of operation.

rtunity to optimize the production capacity and product quality, while reducing the costs of operation.

Download our free article on this subject here:

For further details and specifications

Choose the PDF files to download